Efficiently Lower Friction With High-Quality Bearing Bushings

Worldwide of equipment and mechanical systems, decreasing rubbing is a key purpose for ideal performance and long life. One effective method to attain this is through the usage of top quality bearing bushings. These usually neglected elements play a crucial function in lessening rubbing and ensuring smooth operation. Not all bearing bushings are produced equal, and the option of the appropriate kind can significantly impact the effectiveness of a system. Just how can one browse via the substantial array of options? What are the factors to consider when setting up and selecting bearing bushings? In this discussion, we will explore the importance of birthing bushings, the variables that influence rubbing in equipment, the advantages of utilizing premium bushings, and supply functional ideas for choosing and mounting them. So, allow us start this trip to find how top notch bearing bushings can effectively reduce friction and boost the efficiency of machinery.

Relevance of Bearing Bushings

Bearing bushings play a critical function in ensuring the efficient and smooth operation of numerous mechanical systems. These tiny elements are designed to minimize rubbing and offer assistance for rotating or moving shafts. By working as a buffer between relocating parts, bearing bushings aid to decrease wear and tear, expand the life expectancy of equipment, and improve general efficiency.

One of the crucial features of birthing bushings is to lower rubbing. Birthing bushings are made from products with reduced coefficients of rubbing, such as bronze or self-lubricating polymers, which aid to minimize this friction.

In addition to reducing friction, bearing bushings also provide support and stability to turning or sliding shafts. They help to maintain proper alignment and avoid excessive motion or vibration, ensuring that the mechanical system operates smoothly and dependably. Without the assistance of birthing bushings, the shafts may be susceptible to misalignment, resulting in enhanced friction, wear, and potential damages to the whole system.

Aspects Impacting Friction in Machinery

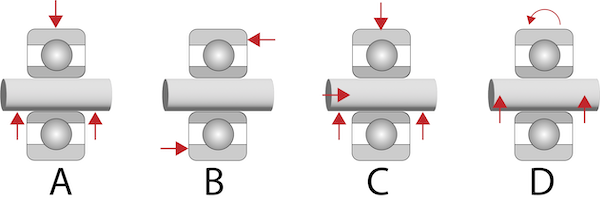

As the smooth operation and long life of equipment depend heavily on decreasing friction, it is crucial to understand the numerous aspects that add to friction in equipment. When two surface areas come right into contact and slide versus each various other, friction is the resistance that takes place. It can cause energy loss, warmth generation, and boosted deterioration of machine parts. There are a number of variables that impact friction in equipment.

The initial element is surface roughness. When the surfaces of 2 elements are harsh, the get in touch with location increases, causing higher rubbing. Sprucing up or lubing the surface areas can decrease rubbing by smoothing out the roughness.

The second variable is the type and high quality of lubrication. Proper lubrication develops a slim film between the relocating surfaces, lowering direct call and minimizing friction. The thickness and temperature of the lube additionally play a significant function in rubbing decrease.

The third aspect is the lots or stress put on the surfaces. Greater lots increase the surface get in touch with location and the rubbing force. Proper tons circulation and harmonizing are essential to avoid extreme rubbing.

In addition, the speed of the moving parts, the material properties of the components, and the environmental conditions, such as temperature and humidity, can also influence friction in machinery.

Benefits of Utilizing High-Quality Bearing Bushings

Utilizing top notch bearing bushings offers various benefits in regards to enhancing machinery performance and longevity. These advantages make buying high-quality bearing bushings a wise decision for companies operating heavy machinery.

Among the key advantages of making use of high-grade bearing bushings is reduced rubbing. Rubbing is a significant aspect that can cause deterioration on machinery components, resulting in lowered efficiency and boosted maintenance costs. Top quality bearing bushings are designed to minimize rubbing, permitting for smoother operation and decreasing the risk of damages to equipment parts.

Additionally, premium bearing bushings add to enhanced efficiency. By lowering rubbing, these bushings help to maximize power transfer within the machinery, causing boosted efficiency and reduced power usage. This not just enhances overall efficiency however also assists to decrease operational costs in the lengthy run.

Sorts Of High-Quality Bearing Bushings

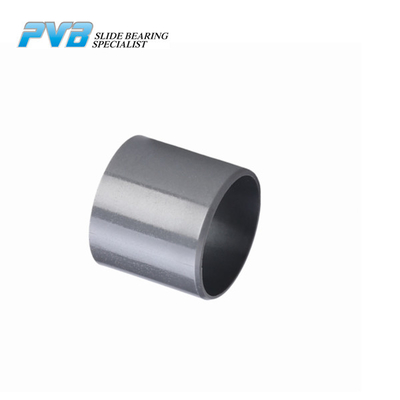

There are numerous distinctive varieties of high-grade bearing bushings readily available on the market. One prominent type is the simple bearing bushing, likewise known as a check over here sleeve bearing or journal bearing.

One more type is the moving component bearing bushing, which is commonly utilized in applications where higher speeds and much heavier tons are entailed. This kind of bushing incorporates moving components such as rollers or spheres, which permit smoother and much more effective rotation.

Self-lubricating bearing bushings are also widely utilized, especially in applications where maintenance is hard or pricey. These bushings are constructed from products such as PTFE, nylon, or graphite and have built-in lubrication properties, eliminating the demand for external lubrication.

Tips for Picking and Putting Up Bearing Bushings

One crucial consideration when picking and setting up high-grade bearing bushings is to carefully review the certain requirements and applications, constructing upon the knowledge of the unique kinds pointed out in the previous subtopic. To start with, it is critical to understand the lots ability and rate needs of the application. This will assist in identifying the proper product and layout of the bearing bushing to make sure ideal efficiency and longevity.

An additional variable to think about is the operating atmosphere. Whether the bushings will be exposed to heats, corrosive chemicals, or severe climate condition, it is necessary to choose a material that can withstand such conditions without compromising its efficiency.

Additionally, the setup process plays a significant function in the effectiveness of the bearing bushings. It is important to guarantee correct placement and fitment to stop any type of unneeded stress and anxiety or imbalance that could cause early failing. bronze bushing. Lubrication is additionally critical to minimize friction and wear between the bushing and the turning shaft

Finally, routine assessment and upkeep are essential to ensure the continued performance of the bearing bushings. This includes checking for signs of wear, monitoring lubrication levels, and dealing with any type of concerns immediately.

Conclusion

In conclusion, top notch bearing bushings play a critical function in lowering friction in equipment. It click for more info is essential to invest in premium bearing bushings to attain optimal performance and durability.

In this discussion, we will certainly explore the significance of birthing bushings, the elements that influence rubbing in machinery, the benefits of making use of top quality bushings, and give functional ideas for selecting and mounting them. Allow us begin on this journey to discover how high-quality bearing bushings can effectively reduce friction and improve the performance of equipment.

Birthing bushings are made from products with low coefficients of rubbing, such as bronze or self-lubricating polymers, which aid to decrease this rubbing. Top quality bearing bushings are made to reduce rubbing, permitting for smoother operation and decreasing the danger of damages to equipment components.